AOC’s strategic emphasis lies in laser and laser application R&D, global sales and marketing endeavors, and the provision of localized customer service and support.

AOC laser product portfolio consists of a broad spectrum of pulsed lasers, including DPSS QS-ns lasers, ultrafast lasers, and MOPA-ns lasers, covering different wavelengths from IR to DUV, and different pulse widths from nanosecond, picosecond to femtosecond. Combining the innovative laser technologies with laser process development capability, AOC can offer complete laser application solutions. With advanced optical design, vision system, motion control system and self-developed software, AOC is now supplying laser micro-processing systems.

AOC products strongly enhance our customer’s capabilities and productivity in consumer electronics, biomedical applications, semiconductor, and other areas. As of today, there are tens thousands laser source and micro-processing system in use in these application fields.

Stripping is essential for certain applications because it removes the outer layer of a material, such as insulation from wires or coatings from surfaces, to expose the underlying material. This process is crucial for ensuring proper electrical conductivity, promoting adhesion in subsequent coating processes, or enabling accurate measurements in analytical techniques. Stripping is often a preparatory step before further processing or application, making it a fundamental technique in many industries, including electronics, aerospace, and automotive as shown in Table 1.

|

Table 1. Application of Stripping |

|

| Electronics | To remove insulation layers from wires or cables, exposing conductive elements for soldering or bonding purposes. |

| Medical devices | To remove insulation layers from wires or cables used in devices such as catheters or implantable components. This process helps in achieving precise removal without damaging the underlying components. |

| Semiconductors | To remove photoresist or other coatings from wafers during fabrication process. This helps in achieving high-resolution patterns and precise removal of unwanted materials. |

| Mechanics | To remove coatings, paints, or adhesives from components such as engine parts. This process helps in refurbishing or reusing parts, as well as in achieving precise and clean removal without damaging the substrate. |

Laser selective stripping, unlike mechanical contact stripping, is a non-contact process offering a clean, precise, and efficient method for removing specific layers or areas of a material. This makes it a valuable process in industries where precision and control are crucial, particularly for thin substrates and wires.

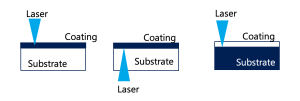

Due to its non-contact nature, the focused laser beam can be precisely directed to the target area for the selective removal of surface coatings as per the design specifications. This flexibility makes the process suitable for workpieces of various sizes, shapes, thicknesses, and material types. Figure 1 depicts a schematic drawing illustrating the typical types of laser stripping mechanisms based on the transparency of the coating and substrate to the employed laser.

Figure 1. Schematic drawings of laser stripping methods based on transparency of coating and substrate to laser

As previously discussed, the essence of laser selective stripping lies in completely removing the coating while preserving the integrity of the underlying substrate. Thus, in this process, selection of laser source is critical. As shown in table 2 are lasers often employed for typical applications.

| Table 2. Lasers employed for typical applications | |

| ns-IR/Green laser | Selectively removing paints, adhesives on thick metal substrates. |

| ns-UV laser | Selectively removing polymer coating from diverse substrates such as metals, plastics, and ceramics. |

| ps-IR/Green laser | Precisely stripping transparent coating from semiconductor substrates with targeted precision. |

| fs-IR/Green laser | Precisely stripping polymer coatings from delicate metal substrates while maintaining stringent quality and precision standards. |

In the realm of laser selective micro-stripping applications, stripping polymer coating from metal wire or mess stands out as the more popular choice.

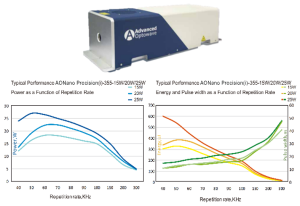

AOC’s short-pulse nanosecond (ns) UV (355nm) laser offers a cost-effective and efficient solution for selectively removing polymer coatings with minimal damage, such as burning or melting, to the surrounding area and underlying substrate, as illustrated in Figure 2.

Fig 2. AONano Precision (i) Series industrial ns-UV (355nm) laser

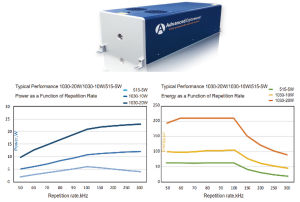

When customers require a stripping process that is free of damage to the surroundings and underlying substrate, ultrafast lasers like picosecond (ps) UV (355nm) or femtosecond (fs) green (515nm) lasers are employed, as shown in Figure 3.

Figure 3. AOFemto Jericho Series Industrial Green (515nm)/IR (1030nm) femtosecond laser

Having collaborated with numerous clients on stripping applications in flexible printing, Si-PV, interventional catheter, and thin copper wire, this article aims to showcase real-world examples of laser stripping. By presenting these illustrations, readers can gain insights into AOC’s laser stripping capabilities and the quality of their work.

In this section, we will introduce a couple of our previous successful examples of laser stripping projects with industrial partners.

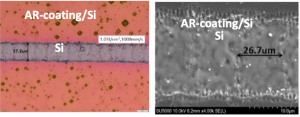

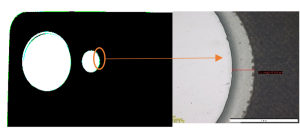

The purpose of this process is to remove the oxide anti-reflection (AR) coating to open a window for electronic connection. The quality requirements are a narrow channel with sharp edges and no melting on the underlying crystal Si surface. AOC’s patented ps-1064nm laser stripping technology was successfully used to achieve damage-free removal of the AR coating. The mechanism of this process involves the interference of the incident beam and the reflected beam from the Si surface, which delaminates the oxide layer without damaging the Si surface.

Figure 4. Optical microscopy image of stripped channel by ps-1064nm laser

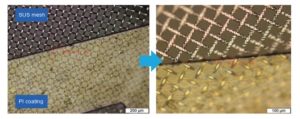

This process is critical for selectively micro screening print for large size applications. It is essential to ensure that no polymer residues are left behind, and there is no damage to both the surrounding polyimide (PI) and the underlying metal braid after stripping off the polyimide cover layer. Failure to meet these criteria can result in serious printing quality issues. Working closely with industry customers, AOC has conducted extensive testing using ns-355nm, ps-355nm, and fs-515nm lasers, respectively. Following the customer’s evaluation, it was determined that ps-355nm and fs-515nm stripping methods meet the required quality standards.

Figure 5 depicts optical microscope images of the ps-UV (355nm) laser selectively removing the polyimide layer from stainless steel (SUS) braid embedded in a flexible PI/SUS sheet. The images demonstrate a clean stripping process with no debris or melting observed on the SUS braid and no burrs or melting at the edge of the PI layer.

Figure 5. Optical microscopy image of stripped PI/SUS flexible screening printing mesh mask using ps-355nm laser

Black ink can be used on a glass display for various purposes, such as creating borders, labels, or decorative elements. UV-curable inks are commonly used for their durability and quick drying properties. Laser stripping of black ink on a glass display is a precise and efficient method, especially for intricate or delicate designs. Because of high absorption of black to almost all wavelengths, cost-effective lasers of ns-1064nm and ns-532nm laser is typically suitable. The mechanism is quite simple. That is, laser heats and vaporizes the ink, breaking it down into gas and leaving the glass surface clean. The process is controlled to avoid overheating or damaging the glass substrate. Figure 6 shows example of stripping black ink coating from display glass, which was requested by an industry customer

Figure 6. Optical microscopy image of the feature of after stripping black ink from glass display using ns-355nm laser

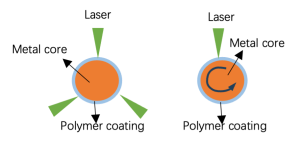

Laser wire stripping has been proven to be highly effective and efficient compared to mechanical processes, particularly for thin wires with diameters in the millimeter range or less. Unlike stripping on flat surfaces, wire stripping may involve multiple laser beams incident on a static wire from two or three directions or rotating the wires to expose them to a focused static laser beam, as shown in Figure 7. It has been demonstrated that for stripping polymer coatings from thin metal wires, the use of either a ns-UV laser or an ps/fs-GR/UV laser is preferred to minimize the thermal effects, depending on quality requirements and budget.

Figure 7. Schematic diagram of laser stripping polymer cladding from metal wires

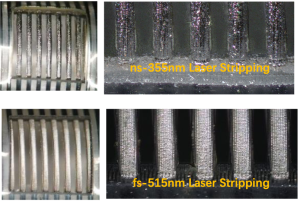

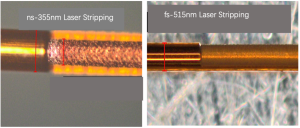

In this section, we will illustrate several typical examples where lasers are the optimal solution. Figure 8 shows an example of stripping polymer cladding from metal-braided wire using ns-355nm and fs-515nm lasers, respectively. It demonstrates a clean and damage-free stripping process achieved with the fs-515nm laser.

Figure 8. Optical microscopy image of the feature after stripping polymer from SUS-braid wire using ns-355nm and fs-515nm laser, respectively

In Figure 9, we observe another instance of polymer cladding removal from copper wire, achieved using both ns-355nm and fs-515nm lasers. The image depicts a smooth surface on the ablated copper wire, with the fs-515nm laser yielding a particularly clean edge.

Figure 9. Optical microscopy image of the feature after stripping polymer from copper wire using ns-355nm and fs-515nm laser, respectively

From a technical standpoint, the fs-515nm laser showcases superiority in wire stripping compared to the ns-355nm laser. However, when considering cost implications, it’s worth noting that the ns-355nm laser has greater popularity in this application. Exceptions may arise in specific circumstances where the unique capabilities of the fs-515nm laser become indispensable.

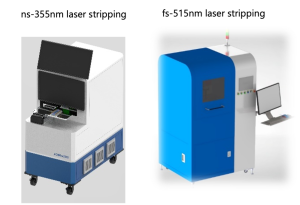

As a laser micro-processing solution provider, AOC offers customers laser sources, process development, and processing systems. To meet diverse industry needs, AOC has developed compact and cost-effective ns-355nm and fs-515nm laser wire stripping systems, shown in Figure 10.

Figure 10. AOC designed ns-355nm and fs-515nm laser wire stripping system

In conclusion, after a decade of collective efforts in exploring laser ablation-based micro-processing technology, AOC has developed a comprehensive laser wire stripping solution through collaboration with industry customers.

Contact: Jack Zhang, (Ph.D.)

Email: JZhang@a-optowave.com