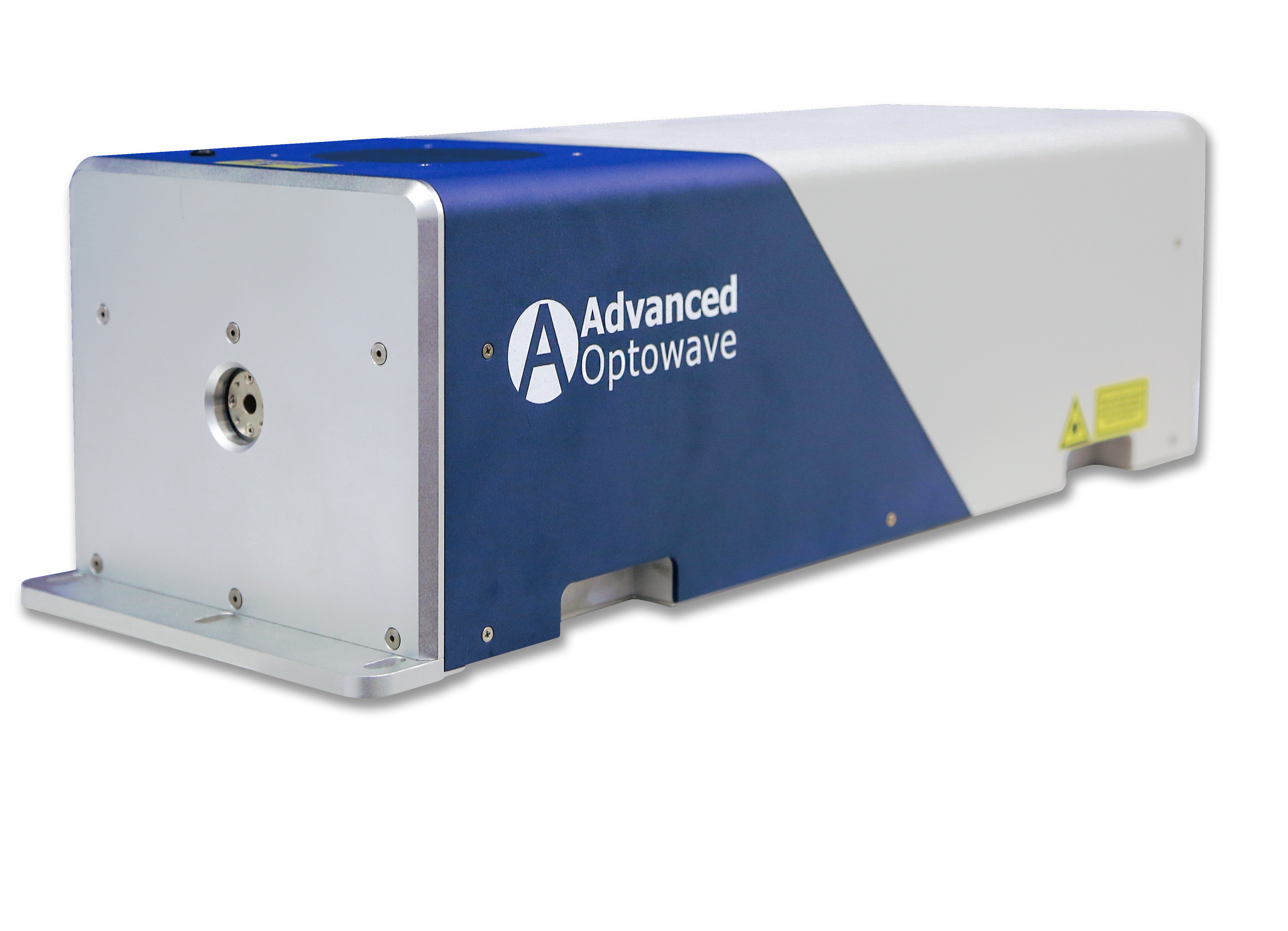

AONano Precision-532

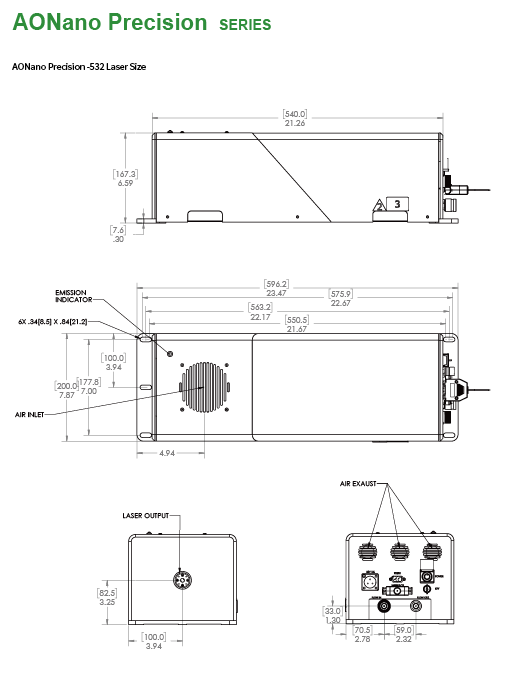

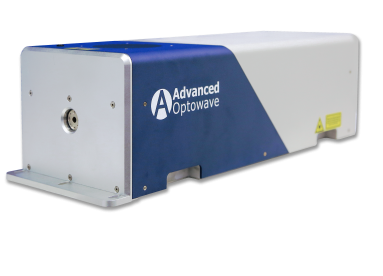

AONano Precision-532 laser adopts a compact all-in-one design, which effectively simplifies the design of the customer's equipment, making the installation and integration easier and more convenient. The design that organically combines the laser's electrical control part and the optical part greatly reduces the risk of possible failure caused by excessive external wiring connections and improves the overall stability of the user's equipment. The water-cooled cooling style, solid cavity structure, and stable design make it a perfect combination of performance and stability and is applied for various challenging applications.

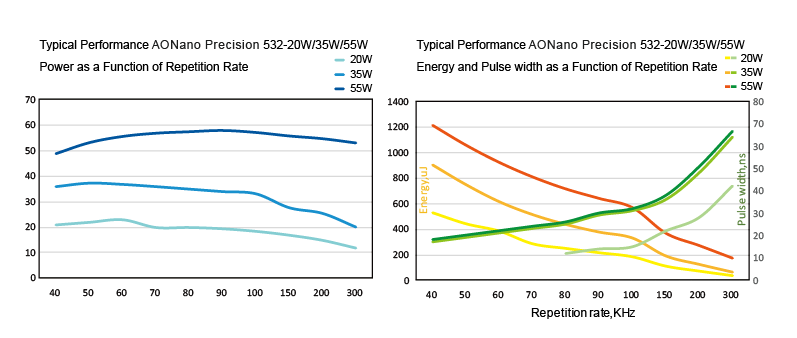

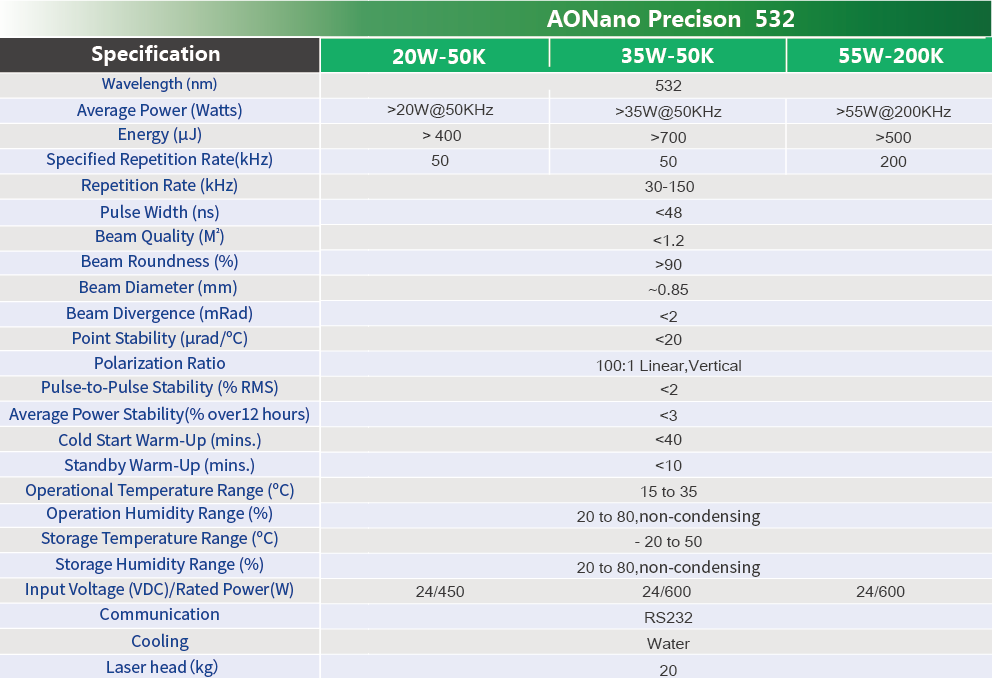

AONano Precision series is an upgraded version of the original AWAVE laser, with excellent performance. In addition to maintaining the original excellent beam quality (M2<1.2), it also expanded the laser's operating frequency range from 30-150kHz to 20-300kHz, and optimized the laser power at high frequency, so that the laser can adapt to more application and improve the processing efficiency of customers. It adopts Inno Laser’s world-leading inner cavity harmonic generation technology and its industry-leading photoelectric conversion efficiency, making it a solid-state UV laser with the lowest energy consumption.

The power ranges from 20w, 35w, up to 55 watts, which can meet most requirements to the power of customers for nanosecond Green lasers. The AONano Precision series lasers can be operated with TTL level signals and PWM pulse width modulation signals. The PWF function allows customers to adjust the power output of the laser in the internal control mode through software.

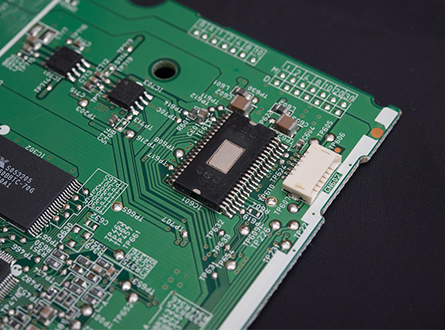

The compact all-in-one design, excellent beam quality, wide repetition rate, flexible control mode, and comprehensive power coverage make it a perfect choice for the application of FPC/PCB cutting, solar cell processing, wafer processing, etc.